Introduction to Innovative Approaches for Responsible PPE Waste Disposal

The surge in demand for Personal Protective Equipment (PPE) has been a defining characteristic of the global response to health emergencies, particularly the COVID-19 pandemic. While PPE such as masks, gloves, gowns, and face shields have become vital for safeguarding public health, they have also triggered a significant PPE waste management challenge worldwide. Traditional disposal methods often lead to environmental hazards and public health risks, making it crucial to adopt innovative approaches to responsible PPE waste disposal.

This comprehensive guide explores various forward-thinking methods--ranging from technological advancements to community-driven solutions--that support sustainable, responsible, and eco-friendly PPE waste disposal. Whether you are an environmental enthusiast, policy maker, healthcare professional, or concerned citizen, understanding these techniques is both timely and essential.

The Global Challenge of PPE Waste

As the usage of disposable PPE has skyrocketed, so has the volume of associated waste. According to recent studies, billions of face masks and gloves are discarded monthly. Unfortunately, much of this medical waste finds its way into landfills and oceans, posing threats to wildlife, clogging drainage systems, and potentially spreading pathogens.

- Non-biodegradable materials: Most PPE is made from plastics like polypropylene, which can persist in the environment for hundreds of years.

- Hazardous waste: Used PPE can carry infectious agents, making improper disposal a public health risk.

- Environmental pollution: Microplastics from degraded PPE contaminate soil and water sources.

Given these pressing issues, responsible PPE waste disposal is no longer optional--it's an urgent need that demands innovative, scalable, and sustainable solutions.

Traditional PPE Waste Disposal Methods

Before delving into innovative solutions, it's important to outline conventional strategies for handling PPE waste. These typically include:

- Incineration

- Landfilling

- Autoclaving (steam sterilization in healthcare settings)

While effective for containing biological hazards, such methods are not environmentally friendly, emitting greenhouse gasses, consuming large amounts of energy, and contributing to longer-term pollution.

Cutting-Edge Solutions for Responsible PPE Waste Disposal

1. Advanced Sterilization and Reprocessing Technologies

Modern sterilization solutions have made it possible to decontaminate and safely reuse certain types of PPE. Techniques include:

- Ultraviolet (UV-C) Germicidal Irradiation: Uses UV-C light to destroy pathogens on PPE surfaces, extending their usable life.

- Vaporized Hydrogen Peroxide Systems: These can safely sterilize masks and shields while maintaining integrity.

- Ozone Treatment: Ozone gas kills bacteria and viruses, and can be deployed in both small-scale and industrial settings.

*By enabling the controlled reuse of PPE, these technologies reduce waste volumes and lessen environmental impact.*

2. Biodegradable and Compostable PPE Innovations

One of the most promising innovations is the development of biodegradable PPE, crafted from materials such as polylactic acid (PLA), cellulose, or other plant-based fibers. These alternatives offer:

- Compostability: The items break down naturally in industrial composting facilities, turning into non-toxic organic matter.

- Lower carbon footprints: Production and disposal contribute less to greenhouse gas emissions.

- Versatile applications: Used in both hospital and community settings without sacrificing protective qualities.

The adoption of biodegradable PPE is a game changer for responsible PPE waste disposal, helping move industries and governments toward a circular economy.

3. Recycling Programs for Single-Use PPE

Recycling single-use PPE has historically been challenging, primarily due to contamination concerns. However, several innovative programs worldwide have demonstrated viable models:

- Mechanical Recycling: Specialized plants sterilize and shred polypropylene masks and gowns, then reprocess the material into items like benches, construction panels, or new PPE products.

- Chemical Recycling: This advanced process breaks down plastics into their chemical components, enabling them to be used as raw materials for new products.

- Closed-Loop Systems: Partners like TerraCycle have launched initiatives allowing organizations and individuals to collect used PPE, which is then professionally recycled or energy-recovered.

Such programs, when scaled, can dramatically reduce the environmental burden of PPE waste.

4. Waste-to-Energy Technologies

Another innovative method harnesses the energy potential of disposed PPE via:

- Pyrolysis: Heating PPE waste in the absence of oxygen converts plastics into usable fuels and reduces reliance on fossil energy sources.

- Gasification: A similar process that transforms waste into syngas, which can generate electricity or heat.

While not a perfect zero-waste strategy, these technologies offer sustainable alternatives to landfilling and open burning, recuperating energy otherwise lost.

5. Community-Based PPE Collection and Upcycling

Grassroots programs play a huge role in responsible PPE disposal, particularly where official waste management infrastructure is lacking. Practices include:

- Neighborhood PPE drop-off bins: Locations where residents safely deposit used PPE for proper collection.

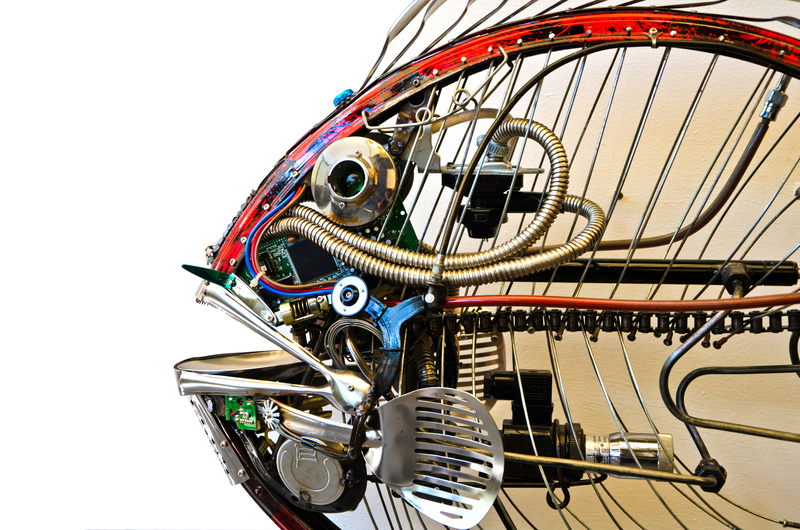

- Community-driven upcycling: Masks and gloves, once sanitized, are creatively transformed into building materials, insulation, or even art installations.

- Education and awareness campaigns: Inform the public about safe disposal practices and environmental impacts.

By empowering communities, these strategies foster stewardship and promote sustainable habits.

Government Policies and Corporate Initiatives

Effective and responsible PPE waste management requires top-down support. Many governments and corporations are taking proactive steps:

- Prescription of separate bins: Mandating distinct containers for PPE to prevent cross-contamination and ensure safer handling.

- Producer responsibility laws: Holding manufacturers accountable for the end-of-life management of their products, spurring eco-design and recycling-friendly innovations.

- Green procurement policies: Prioritizing the purchase of sustainable and reusable PPE in healthcare and governmental operations.

- Incentives for recycling and innovation: Grants, subsidies, and tax breaks for companies that develop new PPE disposal solutions.

These structural changes create an enabling environment for innovative and responsible PPE waste disposal at every level of society.

Emerging Technologies Shaping the Future of PPE Waste Management

Artificial Intelligence (AI) and Robotics

AI-driven sorting systems and robotic arms can now identify and separate contaminated waste from recyclable PPE, significantly improving efficiency and worker safety in waste management facilities.

Internet of Things (IoT) for Waste Tracking

IoT-enabled smart bins monitor fill levels, alerting operators when PPE waste needs to be collected, reducing overflow and enhancing logistics and safety.

Blockchain for Waste Transparency

Blockchain technology can securely record the lifecycle and recycling chain of disposed PPE, ensuring transparency and boosting public trust in responsible disposal initiatives.

Case Studies: Successful Responsible PPE Waste Disposal Initiatives

1. TerraCycle's Zero Waste Box Program

TerraCycle, a pioneer in recycling hard-to-recycle waste, introduced PPE-specific "Zero Waste Boxes." Users fill the box with masks, gloves, and ear plugs, which are then collected, disinfected, and responsibly recycled into raw materials for new products.

2. NHS and RecoMed's PVC Recycling in the UK

The UK's National Health Service teamed with RecoMed to recycle PVC-based PPE. The project transforms clinical waste into traffic cones, roofing membranes, and new medical equipment, closing the loop on plastic use.

3. Indian Startup Sahaayak's Mask Disposal Bins

Recognizing the dangers of littered face masks, Sahaayak placed foot-operated mask disposal bins across Indian cities. The collected masks undergo chemical and autoclave treatments before being upcycled into nonwoven fabrics for industrial applications.

Barriers to Responsible PPE Waste Disposal and How to Overcome Them

- Logistical limitations: Lack of collection points and centralized infrastructure, especially in low-income or rural areas.

- Public awareness: Many individuals are unaware of proper disposal methods, leading to unsafe discarding habits.

- Cost barriers: High-tech solutions and biodegradable alternatives can be more expensive than single-use plastics.

Solutions:

- Expand educational programs

- Scale up pilot projects to nationwide adoption

- Increase government and private sector collaboration

- Incentivize research into cost-effective sustainable materials

By focusing efforts across these fronts, societies can overcome obstacles and steadily progress toward innovative PPE waste solutions.

The Road Ahead: A Call to Action for Sustainable PPE Waste Disposal

As the world continues to navigate pandemics and other public health crises, ensuring a balance between protection and planet is paramount. Embracing innovative approaches--from improved sterilization to eco-friendly materials, advanced recycling, and community engagement--can drive the shift to sustainable PPE waste management.

*Each stakeholder--government, industry, healthcare, and the public--has a unique role in making responsible PPE waste disposal the norm, not the exception.*

Together, through awareness, innovation, and collaboration, we can protect both people and the environment.

Conclusion

The challenge of PPE waste is a modern dilemma, but with innovative, responsible approaches to PPE waste disposal, a cleaner, safer future is possible. By leveraging technology, implementing biodegradable PPE alternatives, supporting recycling programs, adopting waste-to-energy solutions, and fostering community involvement, the world can move towards a model where safeguarding health does not compromise the health of our planet.

Let this be a rallying call for governments, organizations, and individuals to actively participate in the evolution of PPE waste management--because every mask, every glove, and every decision counts.